Formula LAB is the new cutting center with 5 interpolated axes that was created specifically for the processing of stone, synthetic, porcelain stoneware, ceramic and ultra-compact materials, fully satisfying the specificities of the parameters – dimensions and capacities required for trimming and detensioning cuts, multidirectional and curvilinear, inclined at 45°, opening holes and bottoms.

With the aim of meeting the growing demand for new products for building and construction, it is a fact that today the production of ultra-compact stoneware and artificial materials is offering large slabs with ever-increasing dimensions and thicknesses, for which efficient, flexible and cost-effective cutting technologies are required to produce the wide range of finished products that format and consistency of such materials now allow.

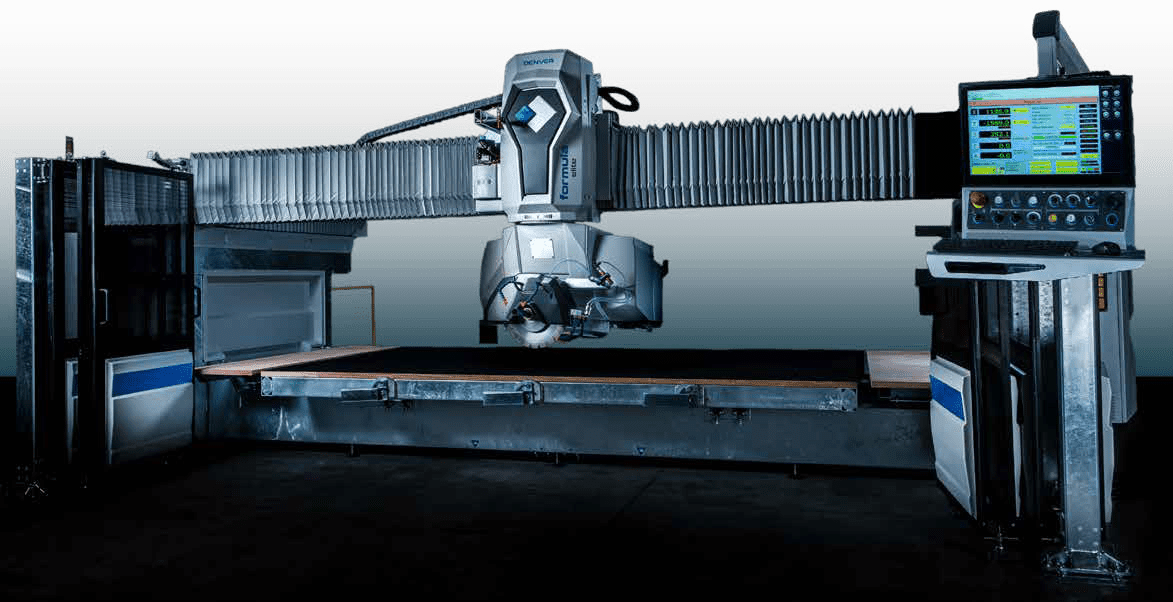

The monobloc structure of the machine ensures maximum rigidity and allows easy and quick installation. All guides and sliding parts are suitably protected with ABS casings (this serves to ensure rust-free, soundproof, ergonomic and aesthetically pleasing machines).

Reliability is ensured by the robustness of the crankcase, CAD design based on finite element analysis and superior machining, which allows a finishing accuracy of one tenth of a millimeter and consistent quality.

Flexibility is guaranteed by the numerical control on the PC, equipped with a complete and versatile intuitive software, which offers the possibility of preset programs and a large database of modifiable drawings and the main engine equipped with tool attachment.

X DRIVE is DENVER technology for 5-axis heads. It uses the high rigidity motor support fork and precision gearboxes with ZERO clearance which, thanks to the CYCLE device, guarantees high torque values and working quality. This technology is controlled by an extremely advanced software called TOOL CENTER POINT which, through numerical control, manages the movements of the tool in a simple and continuous way, ensuring extreme precision and rapid positioning, providing excellent finishes with fewer steps. Programming is simple and intuitive with time and cost advantages.

The technical equipment makes Formula LAB the right investment to obtain good performance at an affordable price: barrier of photocells to protect the working field, automatic management of the inclination up to 90 °, hydraulic tilting bench, automatic probes for measuring workpiece thickness and disc diameter, double laser, Easy touch software, Hp.15 motor with 1/2 gas connection for tip tool and adjustable speed.

Find Us

Find Us